Why vibration monitoring?

Vibration monitoring is crucial in construction and demolition due to the heavy machinery used, which produce significant low-frequency vibrations. These vibrations, carrying high energy levels, pose risks to nearby buildings and structures, but can also cause a significant nuisance to local residents.

To reduce these risks, construction sites utilize vibration monitors with sensitive sensors such as the AVA M80 Vibration Monitor (LINK). The key feature of this monitor is real-time feedback, enabling the immediate cessation of construction activities if vibration causes nuisance to local residents or amplitudes near harmful levels to structures. Continuous monitoring is vital for averting potential damage to adjacent structures and infrastructure, ensuring construction projects are conducted safely and without detriment to the surrounding area.

To be able to act promptly, real-time vibration analysis in construction is a perfect way for the immediate evaluation of vibration amplitude. These systems also record waveforms which will help stakeholders find the dominant frequency. This function enables instant comparison of recorded signals to set thresholds. Exceeding these thresholds triggers alerts via email or SMS, necessitating immediate cessation of construction to avert damage to nearby structures.

What are the sources of vibration?

Vibration monitoring in construction is primarily concerned with managing ground vibration, which includes various sources and impacts. These applications highlight the need for accurate monitoring and control to protect buildings and ensure the safety and comfort of individuals in the vicinity.

Below are some common sources of vibration activity.

- Blasting: This ground-borne vibration type, with frequencies of 1-300 Hz and peak particle velocity (PPV) up to 50 mm/s (2 in/s), can significantly impact structures, especially those resonating at frequencies of 6-10 Hz. Additionally, the air overpressure from explosions, with frequencies as low as 40 Hz, can damage building windows and facades.

- Pile Driving: Caused by pile driving operations, these vibrations have frequencies of 1 to 100 Hz and PPV values reaching 100 mm/s (4 in/s). They pose particular danger at low frequencies around 20 Hz, threatening the integrity of nearby structures.

- Concrete Crunchers and Rock Machinery: Operating at lower frequencies, concrete crunchers work around 3 Hz, while rock machinery causes ground vibrations of 1-100 Hz and PPV up to 100 mm/s (2 in/s). This equipment can impact both the construction site and adjacent areas.

- Construction Work Inside Buildings: Internal building activities can produce vibrations of 1-300 Hz with PPV up to 30 mm/s (1.2 in/s), posing risks to the building and its immediate environment.

- Heavy Trucks: The transit of heavy trucks to and from the construction site generates low-frequency vibrations (1-100 Hz) with PPV potentially reaching 50 mm/s (2 in/s). These vibrations are of particular concern for roads, infrastructure, and buildings in proximity.

Where do limits come from?

Monitoring construction vibration is crucial for ensuring structural integrity and adherence to local and international standards, including Germany’s DIN, the UK’s BS, the USBM RI-8507 and ISEE in the US, and ISO standards globally. The most recognized standards for structural vibration, such as ISO 4866, BS 5228-2 from the UK, and Germany’s DIN 4150-3, employ the Peak Particle Velocity (PPV) method in conjunction with FFT analysis to determine the Dominant Frequency.

The PPV method, as outlined in DIN 4150-3 and BS 5228-2, measures the highest vibration velocity amplitude within the time-domain signal. This involves performing an FFT analysis where the FFT window’s centre is precisely aligned with the PPV, providing both the PPV value and its corresponding Dominant Frequency for each axis (X, Y, Z).

Cosmetic Damage: How to avoid vibration breaches

Accurate comprehension of vibration levels and limits is crucial. This means Therefore, it is essential to ensure that the vibration measuring device is installed correctly. The AVA-M80 vibration monitor, equipped with a tri-axial geophone, is our preferred device for safeguarding buildings and structures. It measures Peak Particle Velocity in three directions and offers real-time email and SMS alerts, in addition to an impressive eight-month battery life.

As mentioned previously, in the UK vibration limits are specified in the ‘BS 5228-2 for construction and demolition activities on open sites’. When measuring according to this standard and guideline, focusing solely on the limits, certain steps must be followed. These points are broad observations of the standard, and it is advisable to employ a qualified engineer to conduct an assessment on the project and practices before initiating any work, as these notes do not encompass all critical considerations for vibration measurement.

Step 1: Determine the subject of protection. BS 5228-2 contains two tables outlining specific limits: one for human perception and another for structural damage. These steps focus on structural damage.

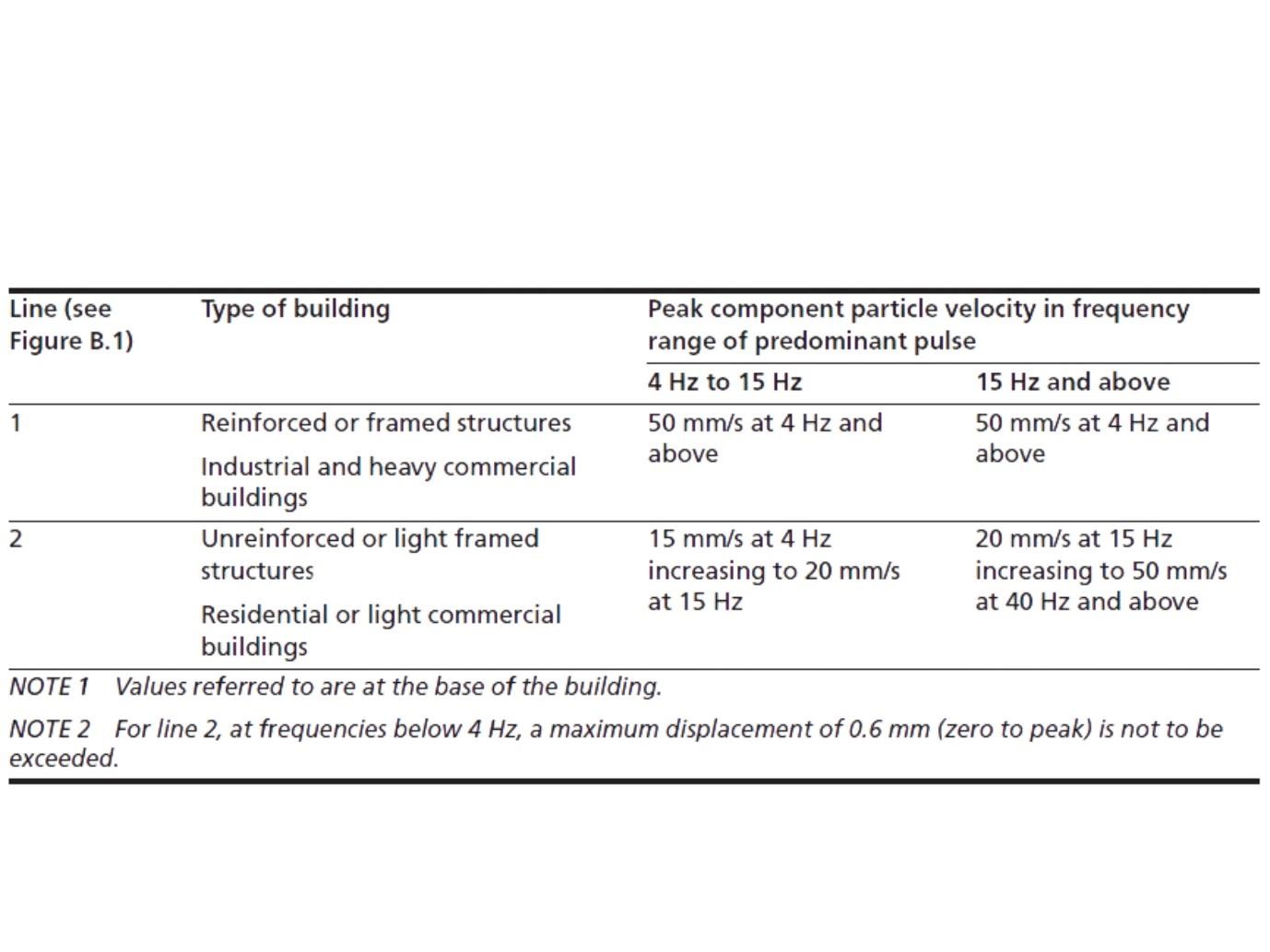

Step 2: Ascertain the building category. What are the established limits? These are detailed in the table below.

Figure 1: Transient vibration guide values for cosmetic damage

Step 3: Observe the frequency range and adjust the limits as necessary. It’s important to note that vibration limits increase with frequency; however, a lower limit is typically set for all frequencies, provided that the vibration sensor is configured with the correct filter profile and standard. Knowing the frequency and level can help prevent breaches, which is the purpose of the AVA-M80 monitor’s ability to gather this dataset along with vibration waveform data.

The table below shows that at 4Hz, the vibration limit for cosmetic damage is 15 mm/s (0.6 in/s), which increases to 50mm/s (2 in/s) at 40Hz.

Figure 2: Transient vibration guide values for cosmetic damage chart

Note that figure 1 and 2 pertains to cosmetic damage. Cosmetic damage typically involves the development of hairline cracks on drywall surfaces or the widening of existing cracks in plaster or drywall; it also includes the appearance of hairline cracks in the mortar joints of brick or concrete block constructions.

The standard also details other types of damage, such as:

• Minor damage, which includes the formation of significant cracks or the loosening and falling of plaster or drywall surfaces, as well as cracks through bricks or concrete blocks.

• Major damage, which affects structural elements of the building and may involve cracks in support columns, loosening of joints, splaying of masonry cracks, and similar issues.

Regarding the thresholds for Minor and Major damage, the standard provides specific guidelines.

‘Minor damage is possible at vibration magnitudes which are greater than twice those given in figure 1, and major damage to a building structure can occur at values greater than four times the tabulated values. Definitions of the damage categories are presented in BS 7385-1:1990, 9.9.’

PPV and human response

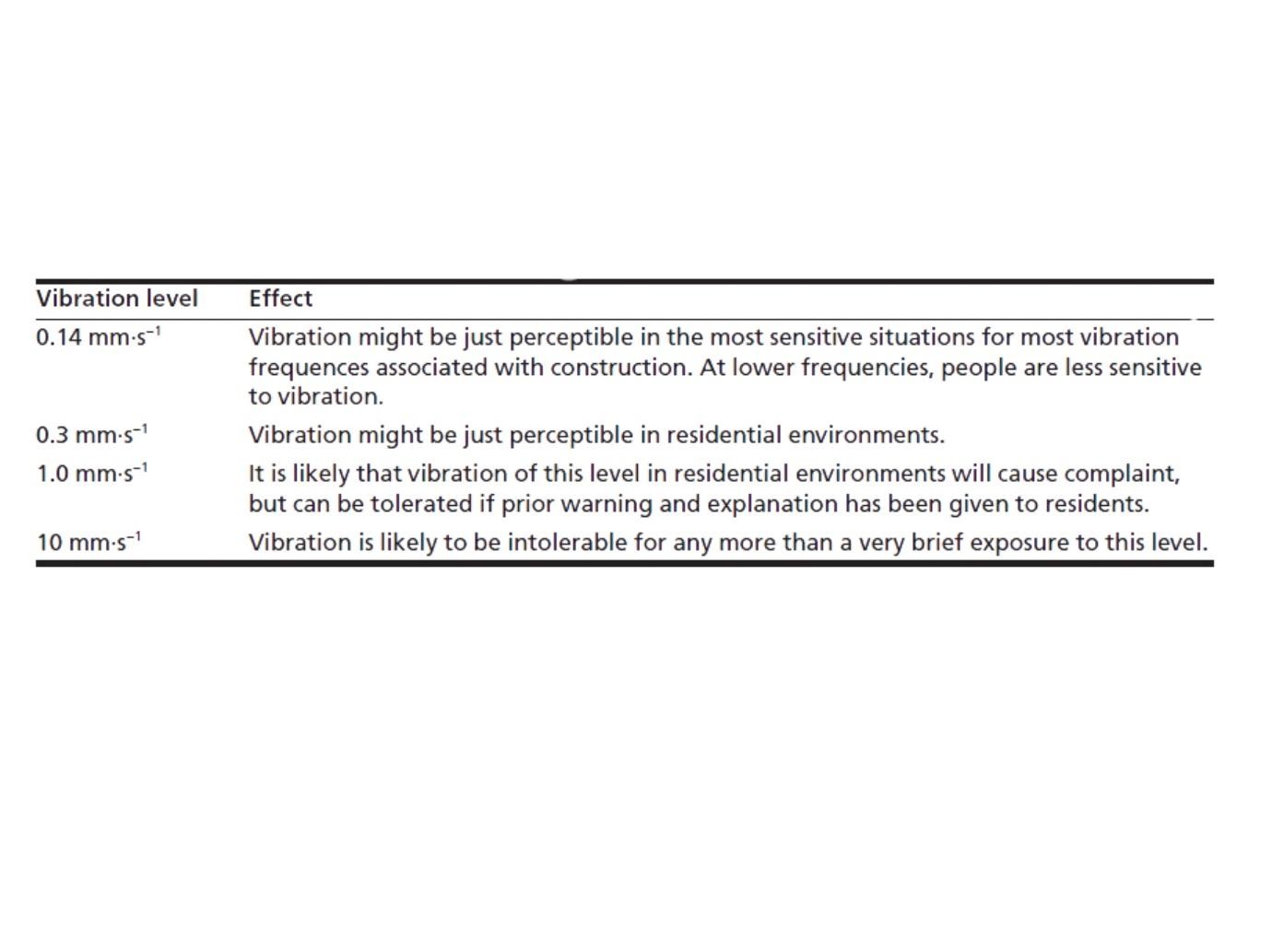

Cosmetic damage is not the only concern when it comes to vibration; human reactions are also significant and warrant attention. Generally, the threshold for concern is lower than that for cosmetic damage and varies depending on the activities occurring in the vicinity where people reside.

Humans are quite sensitive to vibrations, with the perception threshold typically lying between 0.14 mm/s and 0.3 mm/s (0.0055 and 0.0118 in/s) peak particle velocity (PPV). Vibrations exceeding these levels can cause disturbances, startle people, lead to annoyance, or disrupt work. At elevated levels, vibrations may be deemed unpleasant or even painful. In residential settings, vibrations can cause anxiety over potential structural damage.

The distinction between barely perceptible vibrations and those causing annoyance is notable. Often, a low rate of complaints is linked to awareness. When local residents are well-informed and precise start and stop times for vibration-causing activities are shared, they are more likely to tolerate higher levels of vibration. Conversely, in rural areas where background vibrations are minimal, even low levels of vibration can be noticeable, unlike in bustling cities with constant metro and road traffic vibrations.

The table referenced below provides guidance on the implications of various vibration levels for local residents, as outlined in BS-5228-2.

Figure 3 Guidance on effects of vibration levels

Where are monitors deployed?

The positioning of the systems requires significant resources and accuracy, given the high costs linked to unnecessary halts in construction. Precise predictive maintenance and analysis are crucial for avoiding undue interruptions in the construction schedule.

To improve reliability and minimize false positives, vibration monitoring is typically conducted at multiple points, ideally near the impacted buildings, structures, or local residents. However, this isn’t always possible due to risks of theft, vandalism, or interference with the equipment. Usually, construction sites position the unit within the site’s perimeter, as close as possible to sensitive entities, to securely monitor vibration levels.

When the installation location is deemed secure and free from disturbances, such as an isolated control room, units are positioned nearer to or at the receptor.

Sonitus Systems offers both the hardware and software for a range of environmental parameters on a continual basis, with real-time information available through our Sonitus Cloud dashboard. For more details on our indoor and outdoor noise and air quality monitoring products and services, please contact the team at https://www.sonitussystems.com/contact-us